The Automated Standard Porosimeter allows you to receive a complete, comprehensive and a highly accurate understanding of the pore structure of your materials.

Currently we manufacture our third generation of the Automated Standard Porosimeter 3.2. Proven methodology is implemented in a highly reliable automated system that can provide 24/7 testing. The Automated Standard Porosimeter will give you the edge in material and product development by allowing you to test simulating real environment conditions with variable compressions, temperatures and wetting liquids.

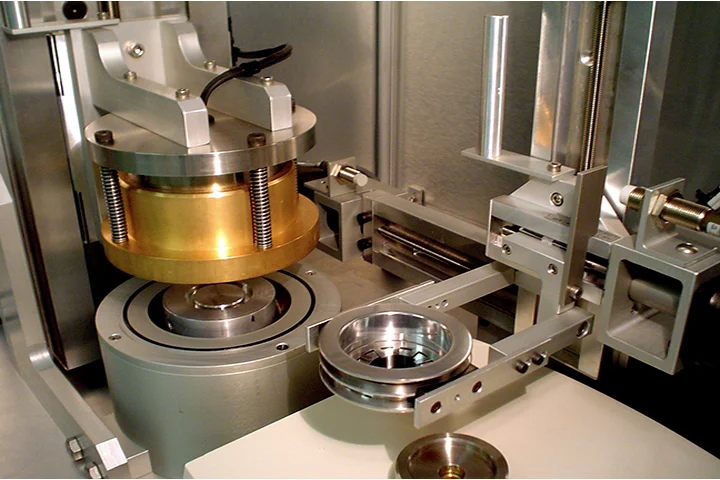

Description of Standard Porosimeter 3.2.

Standard Porosimeter 3.2 is a device where the method of standard porosimetry is realized in the automation mode.

The Standard Porosimeter 3.2 includes a drying chamber, vacuum system, an automatic manipulator for the assembling and disassembling of the stack of samples and for the transfer of the samples from the drying chamber to the balance and back. Any porous and dispersed bodies can be investigated, for example, electrodes, membranes, separators, filters, catalysts, adsorbents, ceramics, metallic ceramics, textiles, pharmaceuticals , construction materials, polymers, geological strata, etc.

Standard Porosimeter 3.2 allows for determination of a variety of information about porous and dispersed bodies: pore volume and specific surface distribution with respect to pore radii, specific surface area, information about a shape (corrugation) of pores, liquid distributions with respect to values of its free binding energy and capillary pressure with the testing material, sorption isotherms, differential characteristics of swelling, contact angle and its dependence on pore radii, characteristics of hydrophobic-hydrophilic properties, etc.

Porosimeter is designed to operate at AC 100V/60Hz, 110V/60Hz or 220V/50Hz depending on country standard. Maximum power is 1 KWatt. Socket connector should have a ground contact.

Mass of Porosimeter: 85 kg

Dimensions: 840*800*660 mm (W*H*D)

The Automated Standard Porosimeter components.

- Drying station

- Weighing station

- Vacuum system

- Manipulation robot

- Protective box

- Block of electronic control and PC

- Holder kit

- Standards and working liquids

- Peripheral equipment for standards and samples pre-treatment.